Solutions

Outstanding solutions for every project, tailored to your needs

Created by our team of experts to ensure optimal performance of your equipment and minimize maintenance costs for your operations. We have a team of specialized designers and engineers, equipped to develop tailored solutions for any type of project. We operate across various sectors, including mining, steel industry, cement plants, power plants, agriculture, and railways. Our expertise allows us to deliver advanced technical solutions that meet the specific needs of each industry, ensuring efficiency, high performance, and durability of equipment.

We have our own manufacturing facility that combines the best equipment and products to deliver top-quality solutions. By leveraging advanced technology and expert craftsmanship, we ensure that every product meets the highest standards of performance, durability, and precision. Our in-house manufacturing capabilities allow us to maintain full control over the production process, ensuring that we consistently deliver reliable, high-performance products tailored to the specific needs of our clients.

We provide regular on-site visits and inspections for all applications and projects developed by our team. Our goal is to ensure the optimal performance and longevity of the materials used in your operations. Through these visits, we monitor the effectiveness of our solutions, identify any potential issues early, and offer proactive support to address them. This hands-on approach guarantees that our products continue to perform at their best, minimizing downtime and maximizing operational efficiency.

Plates coated with Chocky Bar

We have a portfolio containing custom geometry

With a low operating cost, the CHOCKY BAR has excellent weldability and was developed for use in various industrial segments, the bars are produced from a high special alloy with high resistance to abrasion and impact, with a hardness of 700 HB (63HRc).

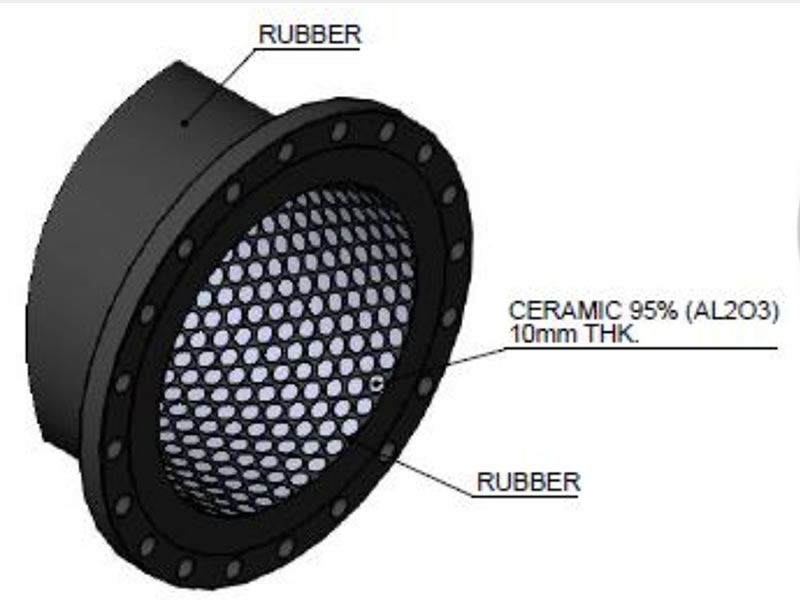

High-alumina Ceramic Piping

We specialize in developing advanced piping systems featuring internal coatings made from high-alumina ceramic

These coatings provide exceptional resistance to abrasion and wear, making them ideal for demanding applications in industries such as mining, cement, and steel production. Our custom solutions are designed to enhance the durability and longevity of your pipelines, ensuring reliable performance even in the harshest conditions.

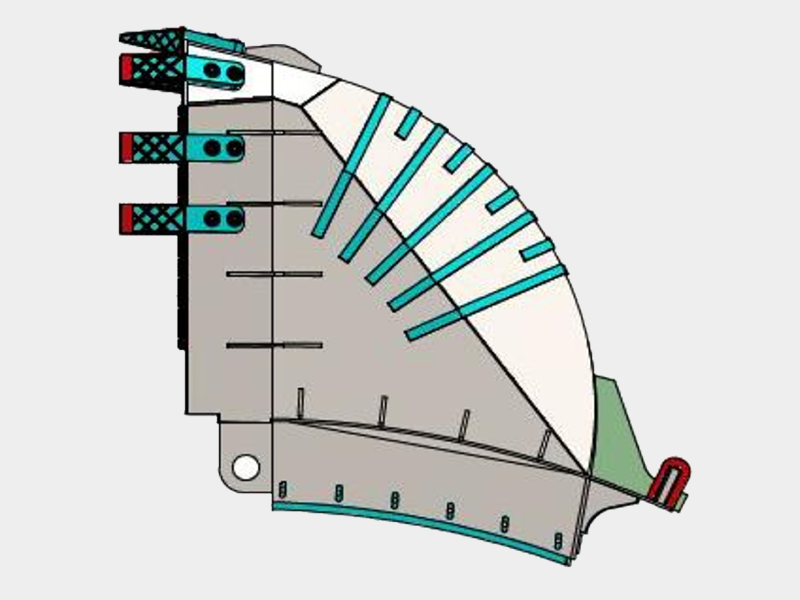

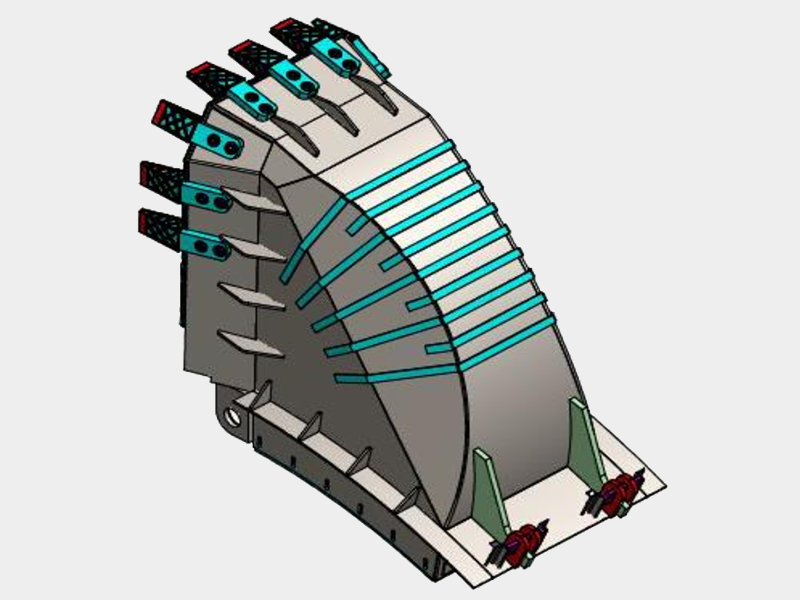

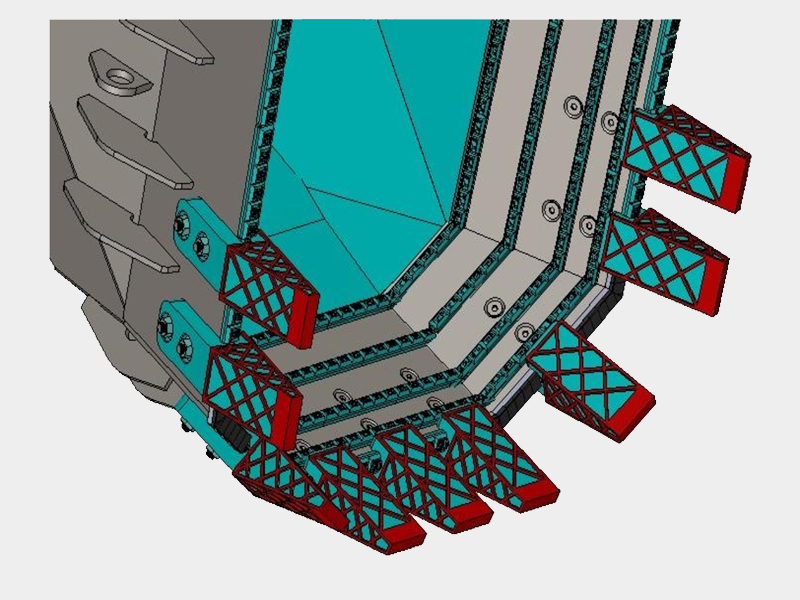

Stack Reclaimer Bucket

This project, specially developed for a stack reclaimer bucket

involved an innovative design with an edge coating using dual materials (Chocky Bar and Tungsten), internal and external coating with Teckno-Ultra X, and high-chromium cast iron teeth coated with Teckno-Ultra X.

The design was carefully developed after an in-depth study of the client's specific needs, considering the high levels of impact and abrasion typical in the operations of such equipment. The use of high-resistance materials like Tungsten and Chocky Bar, combined with Teckno-Ultra X coatings, ensures exceptional performance and extended service life for the bucket. This project not only meets resistance requirements but also optimizes operational efficiency, reducing downtime and maintenance costs.

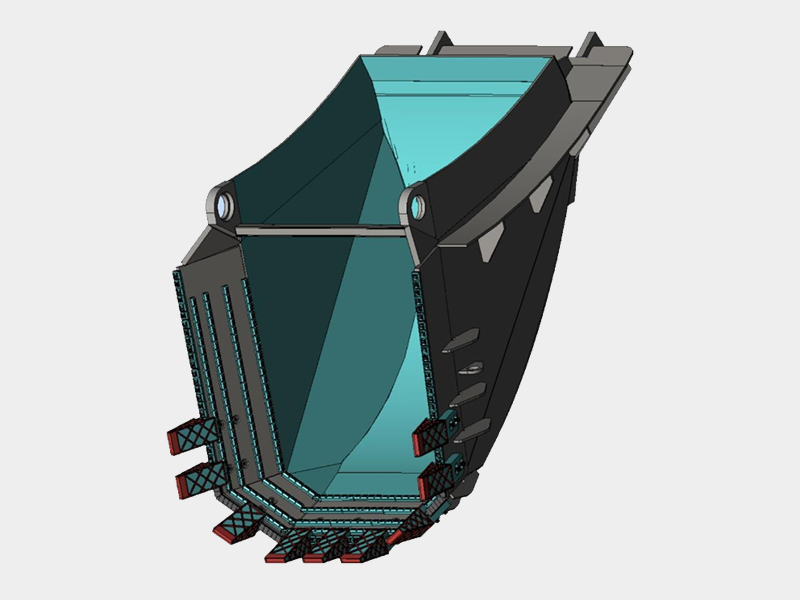

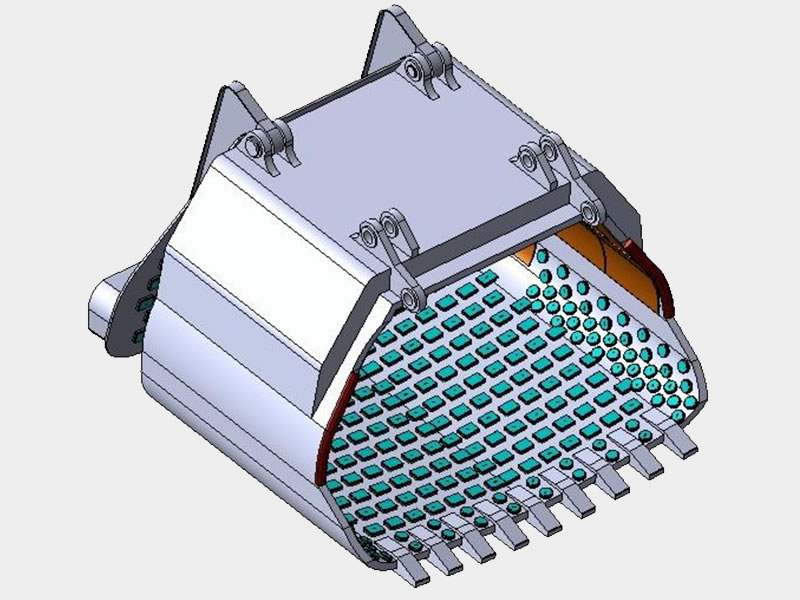

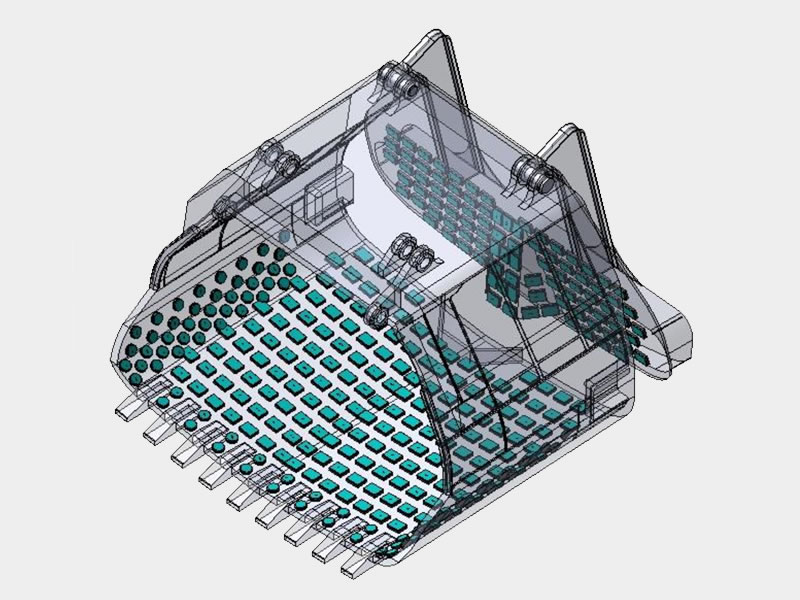

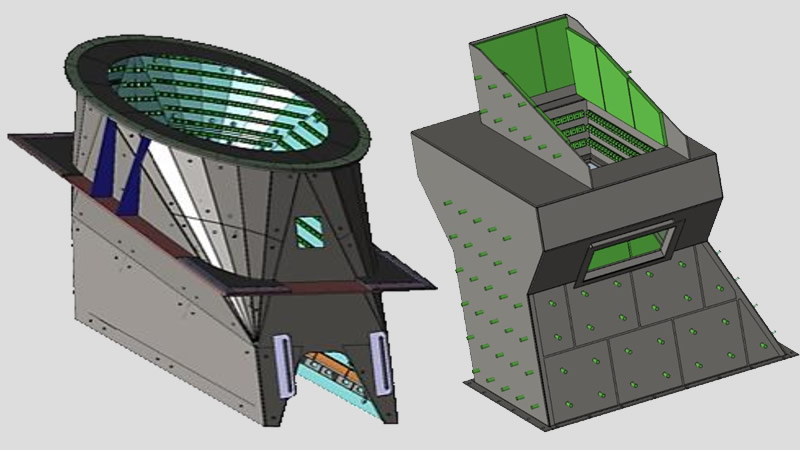

Large bucket

In this advanced project developed for Vale, our engineering team designed a custom solution for a large-capacity ore reclaimer bucket subjected to high impact and severe abrasion

After extensive research, we selected a variety of plates with different shapes and designs to provide optimal wear protection. The tailored approach focused on ensuring maximum durability and performance under extreme conditions.

By partnering closely with Vale, we applied advanced materials such as Chocky Bars and high-resistance coatings, strategically placed to extend the bucket’s service life and improve operational efficiency. This project demonstrates our ability to deliver innovative, high-quality solutions that meet the specific demands of the mining industry, reducing downtime and increasing profitability.

Overlay - Teckno-X

Teckno-X coated pipes are engineered to provide outstanding resistance to abrasion, erosion, and impact

Making them an ideal choice for a variety of demanding applications across industries. These pipes are designed to withstand harsh operating conditions, ensuring enhanced durability and reliability over time.

The system is not only highly effective but also user-friendly, featuring an easy installation process. Additionally, it can be custom-designed to meet the unique requirements of any project, whether for a partial upgrade or a complete pipeline replacement. With Teckno-X, you get a tailored solution that enhances operational efficiency and minimizes downtime.

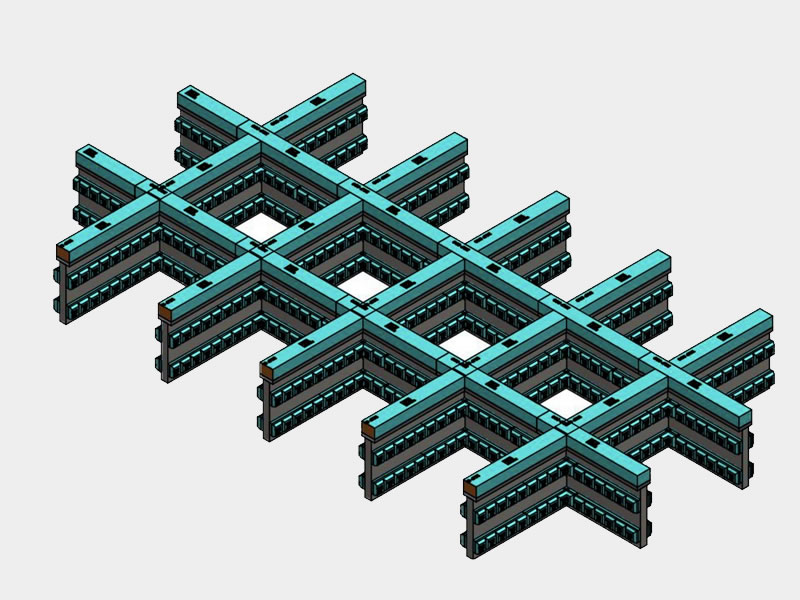

Contingency grilles

Contingency grilles are commonly constructed from low-resistance carbon steel, which tends to have a limited service life due to its vulnerability to wear and impact

To address this issue, we designed a highly durable grille featuring a 30mm Chocky Bar coating with an impressive hardness of 700 HB. This innovative solution significantly enhances the grille's resistance to abrasion and impact, extending its service life and reducing maintenance requirements. This project showcases our commitment to delivering advanced, wear-resistant solutions tailored to the demands of heavy-duty applications.

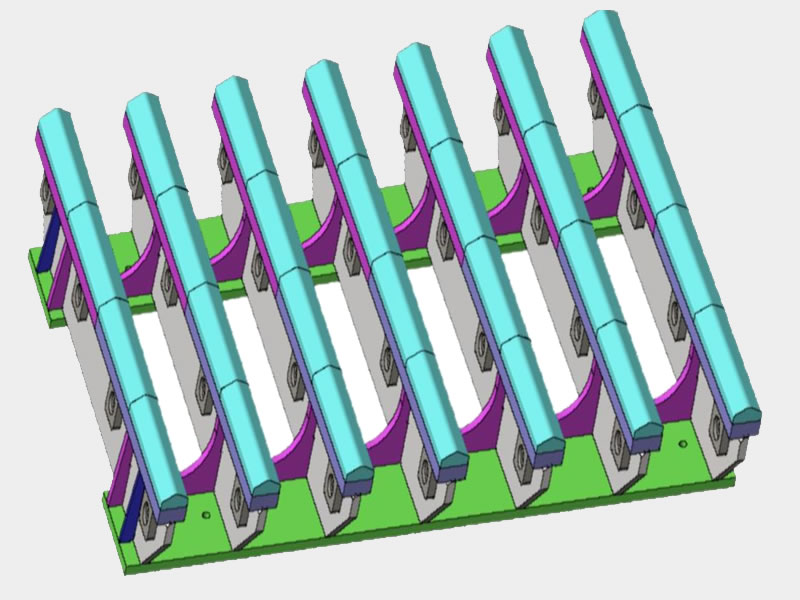

Vibrating Screen

In another innovative project, we addressed the challenges of wear and tear on a vibrating screen by incorporating custom-sized Chocky Bars

These specialized wear-resistant components were precisely tailored to fit the equipment's specific dimensions and operating conditions. By using Chocky Bars with advanced durability and abrasion resistance, we significantly enhanced the screen's service life, reducing the frequency of maintenance and replacement.

This solution not only improved the overall efficiency of the equipment but also demonstrated our expertise in providing tailored, high-performance wear solutions for complex industrial applications.

Our mission is to provide solutions that truly make a difference in your business

At Teckno-Alloys, we believe that customer satisfaction reflects the quality and effectiveness of our solutions. Every project we develop is focused entirely on the specific needs and challenges of our clients. Our commitment is to provide high-performance, wear-resistant products that ensure more efficient, safe, and long-lasting operations.

With a portfolio of innovative solutions for industries such as mining, steel, cement, and more, we have earned the trust of clients worldwide. With each partnership, we deliver not only quality products but also continuous support to ensure consistent results.

"Satisfied Customers, Guaranteed Results" is more than just a motto for us; it is the guiding principle behind everything we do. The trust of our clients is our greatest reward and motivates us to continue delivering solutions that truly make a difference.